General workpiece program appoints G code and ship distance with numerical value directly; for example, GO1 and X100.0. When user macro is used, numerical value can be appointed directly or by variable. When variable is used, variable value can be changed by program or operation in MDI panel.

#1=#2+100

G01 X#1 F300

illustration :

Variable is permitted by computer, but user macro is not. Variable is appointed by variable number ( # ) and latter variable number.

For example : #1

Expression can be used to appoint variable number. Here, expression must be closed in bracket.

For example : #[#1+#2-12]

Variable can be divided into four types according to variable number .

Variable NO. |

Variable type |

Function |

#0 |

dummy variable | The variable is always empty, no value is assigned to the variable. |

#1-#33 |

local variable |

Local variable is only used to store data in macroprogram, such as operation outcome When power is cut, local variable is initialized to empty. And when macroprogram is called, independent variable assign local variable. |

#100-#199 #500-#999 |

common variable |

Common variable has the same meaning in different macro program. when power is cut, variable #100-#199 are initialized to empty. Data of variable #500-#999 is stored even if power is cut. |

#1000 |

system variable |

System variable is used to read and write transformation of all kinds of data when CNC is running, such as tool current position and compensation value. |

Local variable and common variable can have value 0 or values as following shows:

-1047 to -10-29 or -10-2 to -1047

If output oversteps effective range, P/S warning NO.111 is issued.

When variable value is defined in program, decimal can be ignored.

For example : When define #1 = 123 ; actual value of variable #1 is 123.000.

To use variable value in program, variable number follows it after appointing. when using expression to specify variable, put expression in bracket.

For example : G01X[#1+#2]F#3;

Cited variable value is rounded automatically according to minimum setting unit.

For example :

When G00X# is executed as 1/ 1000mm , CNC assign 123456 to #1, and actual instruction value is G00X12346.

To change the sign of cited variable, put negative sign before #.

For example : G00X - #1

When you cite undefined variable, variable and address are all ignored.

For example : When value of variable #1 is 0 and value of #2 is empty, the executing outcome of G00X#1 Y# 2 is G00X0.

For double locus control, system provides every locus individual macro variable. But, some common variables can use two locus at one time according to the setting of parameter N0.6036 and 6037.

When variable value is undefined, this variable becomes empty variable. Variable #0 is always empty. And it can not be written but only be read.

When an undefined variable is cited, address itself is ignored.

| When #1=< empty > | When#1=0 |

G90 X100 Y#1 | G90 X100 Y#1 |

| G90 X100 | G90 X100 Y0 |

(b) Operation

< empty > is the same with 0 except the condition that use < empty > to assign.

| when #1=< empty > | when #1=0 |

#2=#1 #2=< empty > |

#2=#1 #2=0 |

#2=#*5 #2=0 |

#2=#*5 #2=0 |

#2=#1+#1 #2=0 |

#2=#1+#1 #2=0 |

(c)Condition expression

In EQ and NE < empty > is differ from 0.

| when #1=< empty > | When#1=0时 |

| #1EQ#0 true | #1EQ#0 false |

| #1NE#0 true | #1NE#0 false |

| #1GE#0 true | #1GE#0 false |

| #1GT#0 false | #1GT#0 false |

Program number, sequence number and optional segment jumping number can not use variable.

For example : variable can not be used in below conditions :

0#1;

/#2G00X100.0;

N#3Y200.0;

The operations listed below can be executed in variable. expression at the right of operator can include constant and variable composed with function or operator. Variable #j and #k can be assigned by constant. the left variable can be assigned by expression.

| Function | Format | Remark |

Definition Addition |

#i=#j #i=#j+#k; |

|

Subtraction |

#i=#j-#k; | |

Multiplication |

#i=#j*#k; | |

Division |

#i=#j/#k; | |

Sin |

#i=sin[#j; | |

Arcsine |

#i=asin[#j]; | |

Cos |

#i=cos[#j]; | |

| Angle is appointed with degree. 90o30' denote 90.5 degree. | ||

Arccosine |

#i=acos[#j]; | |

Tangent |

#i=tan[#j] | |

Arc tangent |

#i=atan[#j]/[#k] | |

Square root |

#i=SQRT[#j]; | |

Absolute value |

#i=ABS[#j]; | |

Rounding |

#i=ROUNG[#j]; | |

Up rounding |

#i=FIX[#j]; | |

Down rounding |

#i=FUP[#j]; | |

Natural logarithm |

#i=LN[#j]; | |

Exponential function |

#i=EXP[#j]; | |

Or |

#i=#jOR#k; | |

Xor |

#i=#jXOR#k; | Logic operation is executed one bit by one bit according to binary number. |

And |

#i=#jAND#k; | |

Change BCD to BIN |

#i=BIN[#j]; | |

| Used for handshaking with PMC. | ||

Change BIN to BCD |

#i=BCD[#j]; |

Angle unit of function SIN ,COS,ASIN,ACOS,TAN and ATAN is degree, for example 90° 30' denote 90.5 degree.

ARCSIN # i= ASIN[#j]

(1) Numeric area :

When parameter ( NO.6004#0 ) NAT bit place is set to 0, 270° ~ 90°

When parameter ( NO.6004#0 ) NAT bit place is set to 1, - 90° ~ 90°

(2) When #j overstep the range of - 1 to 1, P/S warning NO.111 is issued.

(3) Variable #j can be replaced by constant.

ARCCOS #i=ACOS[#j] numeric area is from 180° to 0° . When #j overstep the range of - 1 to 1, P/S warning NO.111 is issued. Variable #j can be replaced by constant.

N10 G54 G90 G0 S1500 M03

N12 X0 Y0 Z20.

N14 G0 Z1

N16 G1 Z-5. F150.

N18 G41 D1

N20 #1=0

N22 #2=34

N24 #3=24

N26 #4=#2*COS[#1]

N28 #5=#3*SIN[#1]

N30 #10=#4*COS[45]-#5*SIN[45]

N32 #11=#4*SIN[45]+#5*COS[45]

N34 G1 X#10 Y#11

N36 #1=#1+1

N38 IF [#1 LT 370] GOTO26

N40 G40 G1 X0 Y0

N42 G0 Z100

N44 M30

#102=0.

N3#100=0.

#101=0.

#103=200.

#104=400.

G91G28Z0.

G0G90G54X0.Y0.

G43H1Z20.

M3S2000.

N4G0X#100Y#101

G01Z#102F200.

#102=#102-2.

IF[#102EQ-50.]GOTO1

GOTO2

N2

N4X#104F500.

Y#103

X#100

Y#101

#100=#100+10.

#101=#101+10.

#103=#103-10.

#104=#104-10.

IF[#100EQ100.]GOTO3

GOTO4

N3

N1

M5

M9

G91G28Z0.

G28Y0.

M30

O0001

#[#1+1*2]=1

G65P9012L1A0B0.1C4I100J3K0

M30

G54 G90 G00 X[#3] Y0 Z100

S500 M3

G01 Z0 F300

WHILE[#1LE10]DO1

#7= #1/TAN[#5]+#3

G1Z-#1 X#7

#8=#6/2-ROUND[#6/2]

IF[#8EQ0]GOTO10

G1Y0

GOTO20

N10 Y#4

N20#1=#1+#2

#6=#6+1

END1

G0

Z100

G90G0G54X-10.Y0M3S4500

G43Z50.H1M8

#1=0.5

WHILE[#1LE50.]DO1

#2=50.-#1

#3=SQRT[2500.-[#2*#2]]

G1Z-#1F20

X-#3F500

G2I#3

#1=#1+0.5

END1

G0Z50.M5

M30

M03 S500

M06 T01

#1=0

#2=0

G0 Z15

X150 Y0

N11

#2=30*SIN[#1]

#3=30+30*[1-COS[#1]]

G01 Z-#2 F40

G41 X#3 D01

G03 I-#3

G40 G01 X150 Y0

#1=#1+1

IF [#1 LE 90] GOTO 11

G0 Z30

M30

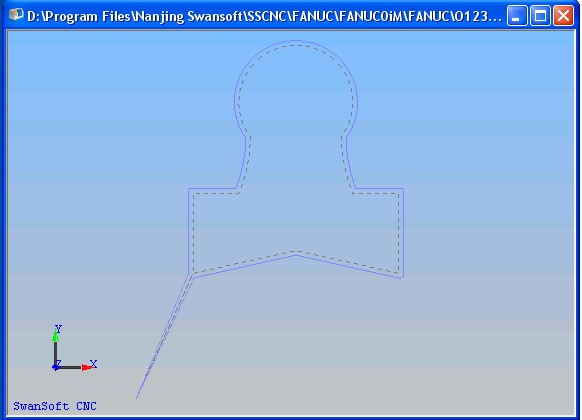

O1234

#12007=4

G92X0Y0Z0

N1G90G17G00G41D07X25.0Y55.0

N2G01Y90.0F150

N3X45.0

N4G03X50.0Y115.0R65.0

N5G02X90.0R-25.0

N6G03X95.0Y90.0R65.0

N7G01X115.0

N8Y55.0

N9X70.0Y65.0

N10X25.0Y55.0

N11G00G40X0Y0