Swansoft Universal Machine Tool (SSUMT)developed by Nanjing Swarth Software Technology Co., Ltd., which includes the X62W1 universal milling machine cutting project, was developed by combining the actual processing and manufacturing experience of machine tool manufacturers with the teaching and training of colleges and universities. Through this software, students can achieve the purpose of physical operation training, and can greatly reduce expensive equipment investment

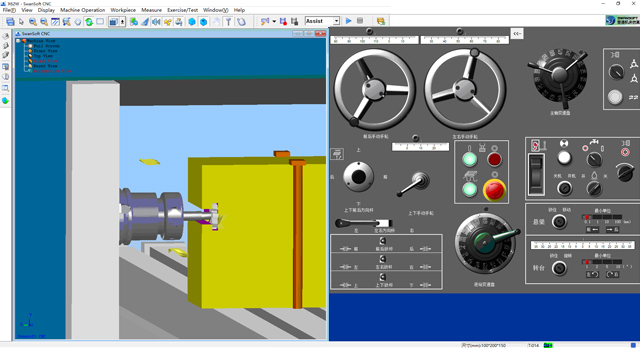

This software has a strong sense of reality. The user can simulate the operation of ordinary machine tools on a PC. The software provides a virtual machine operation panel. In addition to the handwheel feed, the user can operate on the operation panel and the three-dimensional virtual machine at the same time, enabling users to operate in a short time. Master the operation of ordinary machine tools. It can realize keyway milling, face milling, T-slot milling, drilling, etc. In SSUMT network version, the server can obtain the client operation information at any time, and has the functions of examination, practice and broadcasting.

1.Milling machine cylinder, cuboid blank, external CAD shape blank.

2.The whole process of blank definition, workpiece clamping, tool installation and machine operation.

3. Real-time cutting of the workpiece, with the simulation effect of scrap and sound, and the visible simulation effect of the broken tool model.

4. Realistic 3D CNC machine and operation panel to simulate the operation and use of the machine. If you operate on the operation panel,you can see the corresponding handles on the machine follow the action, etc.

5.Using unified database management, the tool library contains hundreds of different shaped milling cutters, and supports user-defined tools.

6. Can measure the size of the finished parts, provide vernier calipers, outside micrometer.

7. Provide different types of clamps: vise, three-jaw chuck, step clamp,edge clamp,vertical edge clamp .

8. Real-time interactive operation of dynamic rotation, zoom, movement, full screen display and other functions.

9. Workpiece selection and clamping.

10. Macro recording and playback on Windows.

11.Recording and playback of AVI files.

12. The first domestic universal machine simulation software to be downloaded for free automatically.

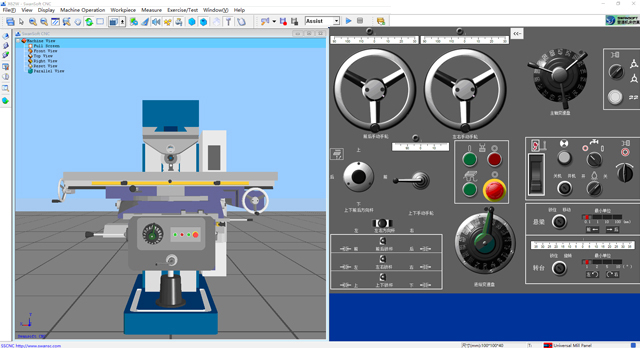

Main Operation interface

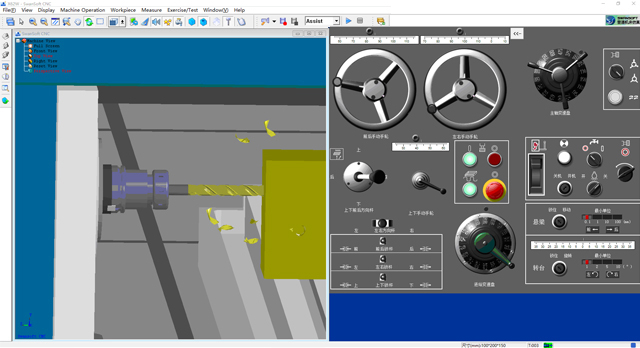

Keyway milling

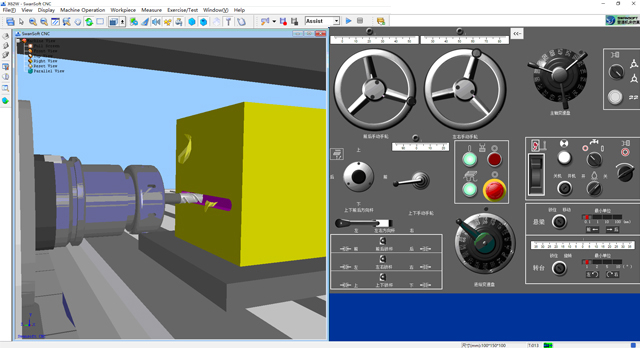

Face milling

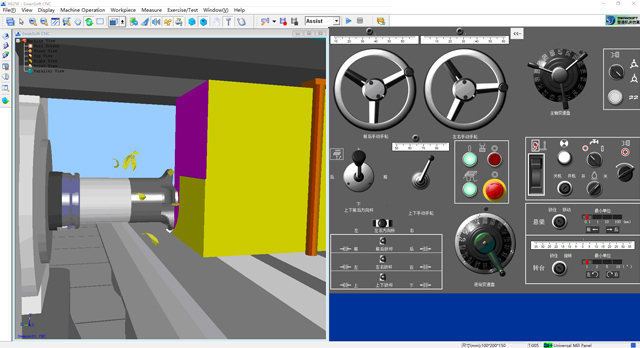

T-slot milling

Drilling