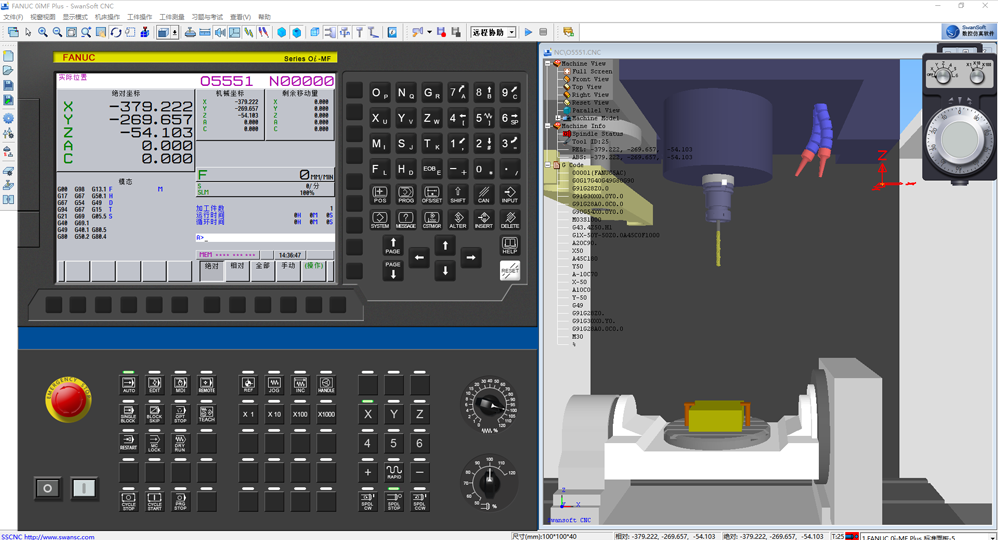

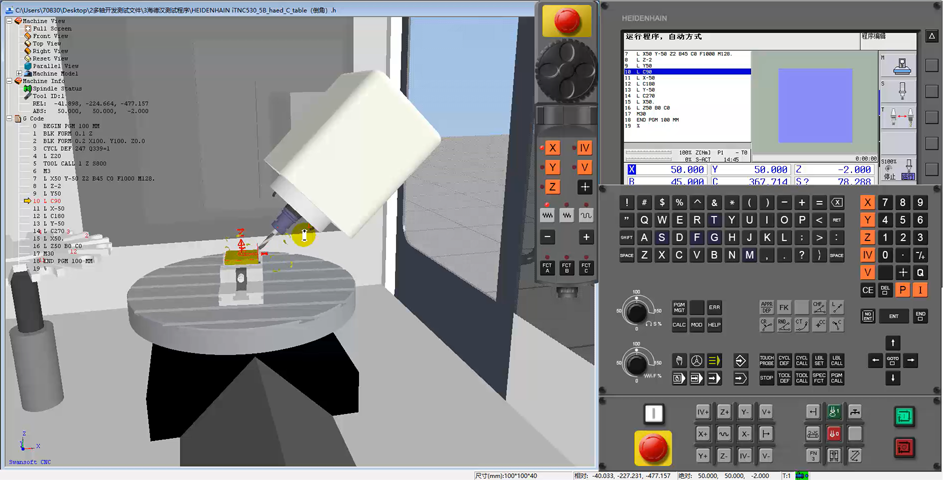

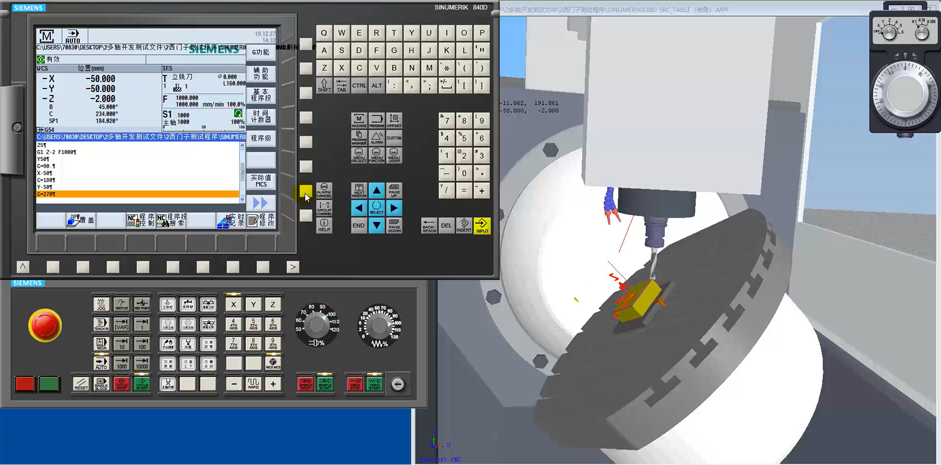

SSMAM can make up for the lack of teaching resources,reduce investment in teaching equipment,Avoiding accidents, etc. It is a widely used auxiliary method and training method in multi-axis CNC teaching. The simulation software not only have the simulation of the CNC control system, should also have the simulation of the machine's operation panel, and model simulation of CNC machine. A virtual multi-axis CNC machine is completely reproduced using the computer's virtual reality technology. Users can use the mouse, keyboard, touch screen and other input devices to simulate the operation of CNC machine. Simulation software can simulate the whole process of CNC machine,including manual searching reference point, manual input, MDI manual input debugging, program protection lock unlock, program editing input or import of external programs, fixture adjustment, blank preparation, workpiece installation, tool preparation, tool installation, setting part zero and virtual machining. Users can simulate the operation of CNC control panels made by different manufacturers. For example, CNC control panels made by manufacturers such as Shenyang Machine Tool Plant and Dalian Machine Tool Plant. The new control panel can be customized free of charge according to the information provided by college users.

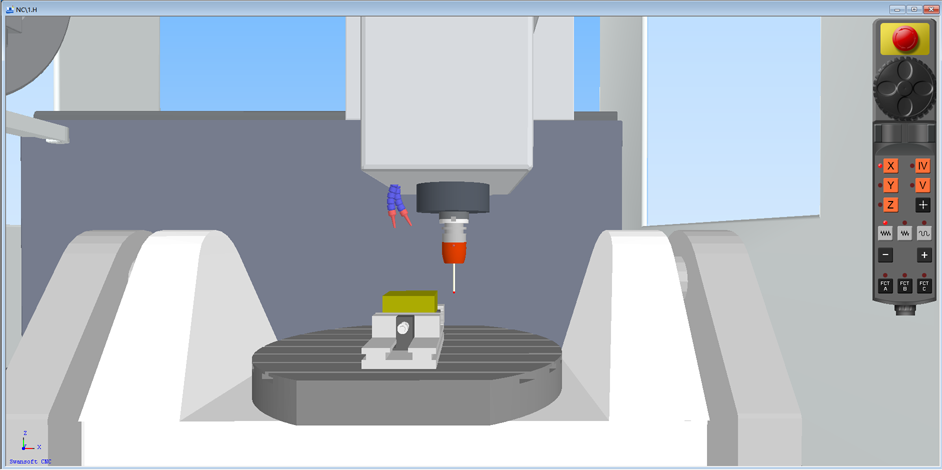

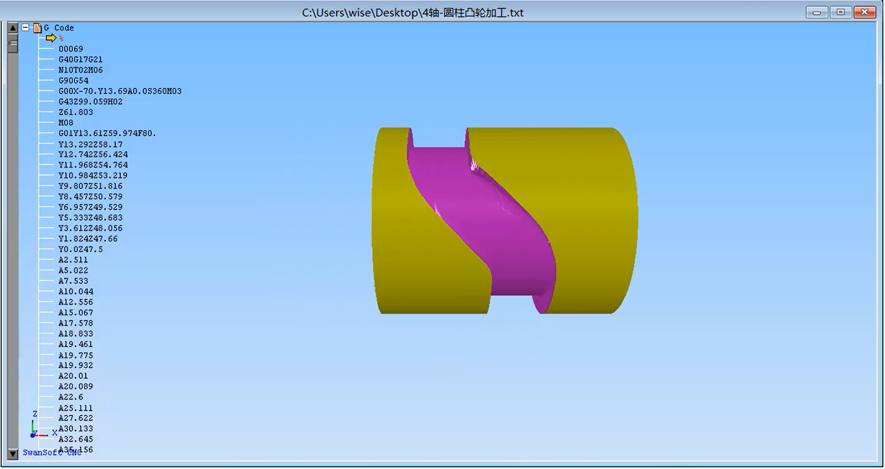

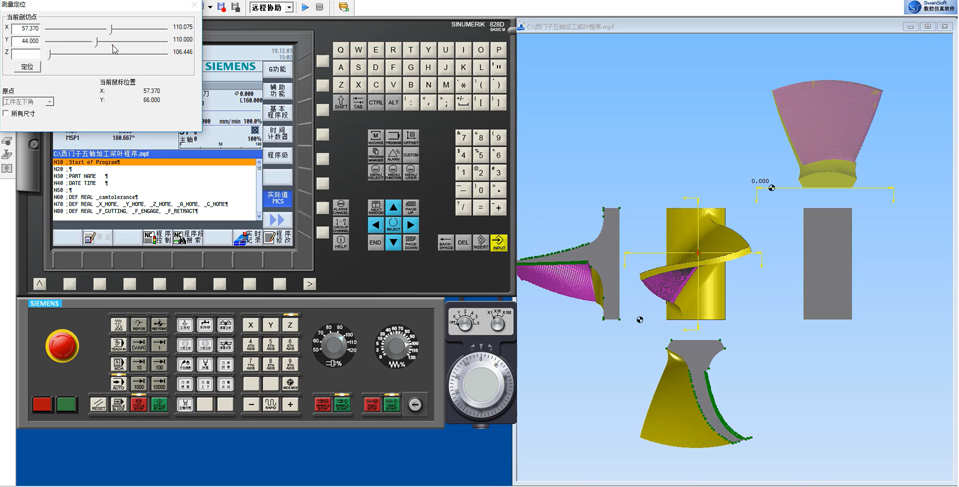

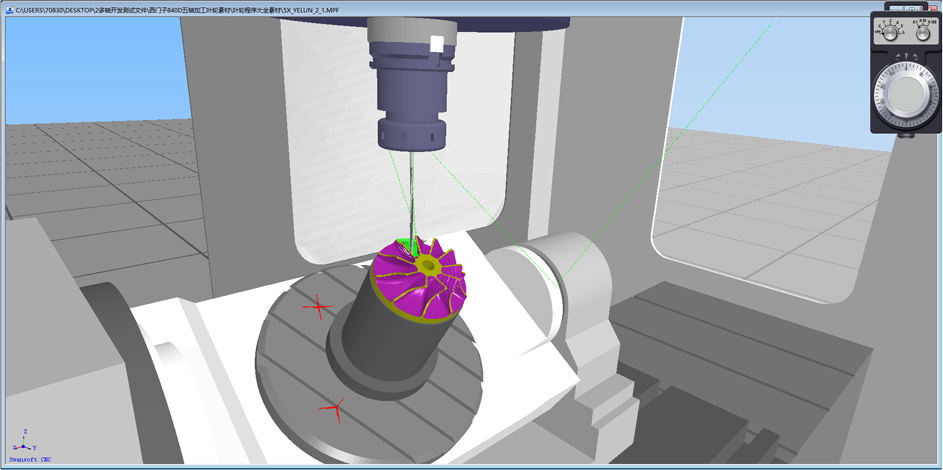

SSMAM can realize the 5-axis simultaneous machining and multi-directional plane positioning machining simulation of the 5-axis machining center, it can Provide dual-table rotary machine structure and dual-swing head machine structure, as well as hybrid single-swing head and single-table machine structure models, and provide important machine parameters of each machine model structure. It can realize the simulation of various four-axis and five-axis machining centers such as A-axis, AC-axis and BC-axis.

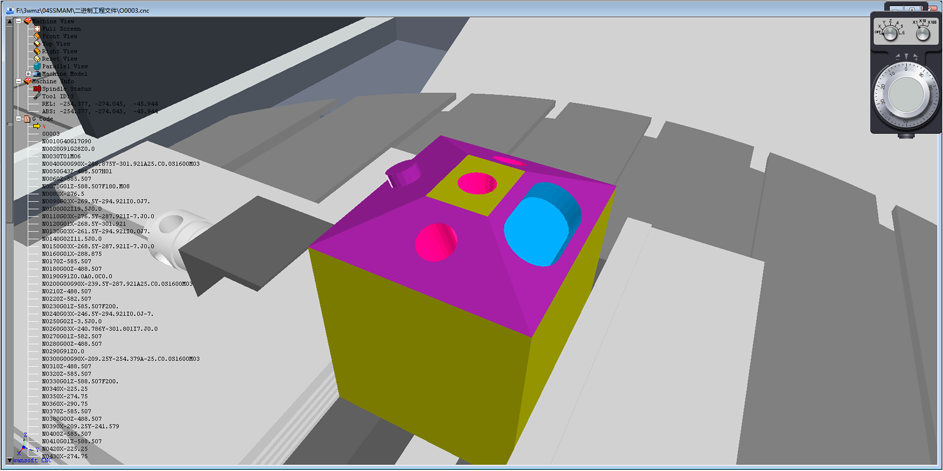

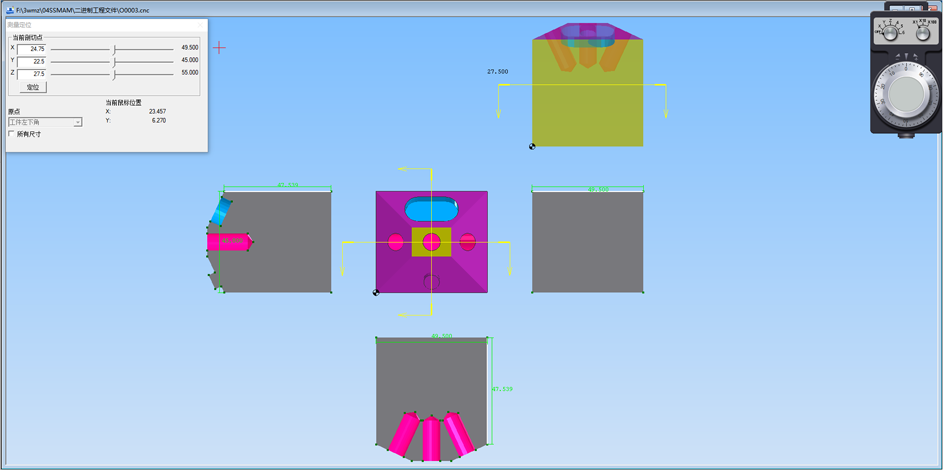

SSMAM provides a 3D display of the tool path, Display of the current coordinate system, display of tool number,function of tool path debugging, function of tool compensation, setting of system parameters such as coordinate system setting, and it has RTCP function.

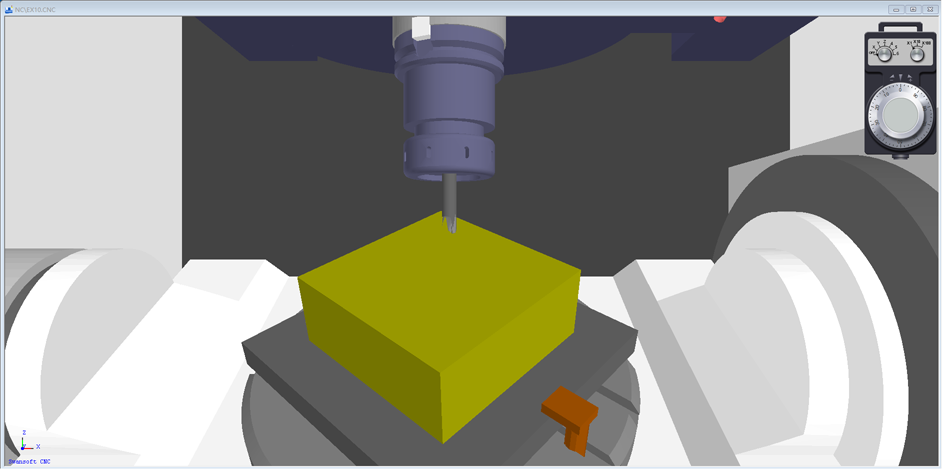

1.Blank definition, fixture calibration, workpiece clamping, workpiece zero setting, tool installation,after the tool collides, you can see the broken tool, manual operation on different panels of the same machine system, etc.

2. Simulation of machining process: including editing, automatic operation, and manual data input(MDI) mode of NC machining programs,real-time cutting of 3D workpieces,display of tool path,provision of tool compensation, coordinate system settings, etc.

3.Machine structure type:providing 4-axis with A-axis rotation structure, 5-axis AC dual-table rotary cradle structure, 5-axis BC dual-table rotary structure, 5-axis BC single-swing head single-table structure, 5-axis BC double-swing head structure.

4.Processing characteristics: with multi-axis simultaneous machining and multi-directional plane positioning machining , curved surface machining, inclined surface machining functions, can also realize one-time clamping, multiple surface machining, several times clamping and turning surface machining.

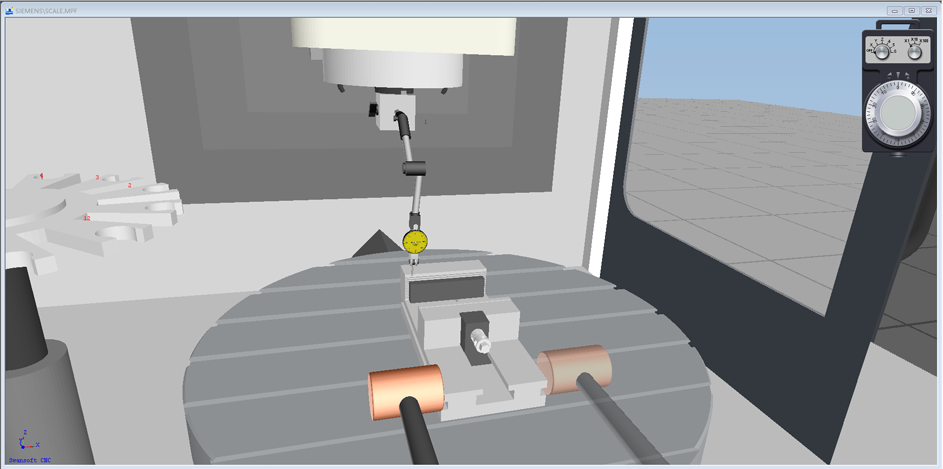

5.Set workpiece zero point tools: such as edge-finder, reference mandrel, Z axis gauge, electronic probe, etc .

6.Program editing: NC programs generated by various CAM software can be imported through DNC, or NC programs can be manually edited through the panel.

7.Program function:1) SIEMENS supports ISO, variable programming, inclined surface machining,tool compensation, drilling cycle, face milling pin cycle, cavity machining cycle.2) MITSUBISHI Supports ISO programming, support canned cycle programming.3)FANUC supports ISO programming, macro instruction programming, canned cycle programming.4)HEIDENHAIN supports ISO programming as well as conversational programming and canned cycles.

8.Blank type: hexahedron, cylinder, support CAD model import of any shape.

9.Fixture types: flat pliers, craft plate, pressure plate, three-jaw chuck, special fixture, etc.

10.Tool library: its type contains drill, flat , ball, bull, chamfer mill, etc. Users can customize the size of the cutter.

11.Measurement: providing a variety of general measurement tools,can measure the processed 3D model, can measure the typical geometrical dimensions of various inclined surfaces of the workpiece. The measurement accuracy reaches 0.001mm.

12.Multi-axis model conversion: 5-axis machine can be imported into 4-axis machine parts.

13.International version: Support multi-language.

14.Extended functions: support interpolation process simulation, dual screen display, touch screen gesture operation.

Teachers register their username and password through SSMAC server, student may login into the network version of SSMAC in any PC using local area network, Teacher can centralize the management and monitor students over local area network.

Teacher may add and edit exercises in SSMAC server. Teacher can transmits the exercises with pictures included to clients (students). Then students write the answers and transmit back to the teacher. SSMAC server builds up an easier and more convienient way for teacher and students to communicate with each other.

SSMAC server records students' operation information according to their registration information. It can control and inquire students' login and logoff and machining operation information.

This system Includes question bank management, test paper management, the test process management as well as the automatical examination marking process.

This Includes test data management, exam permit management, and test result management.